Z purlin roll forming machine

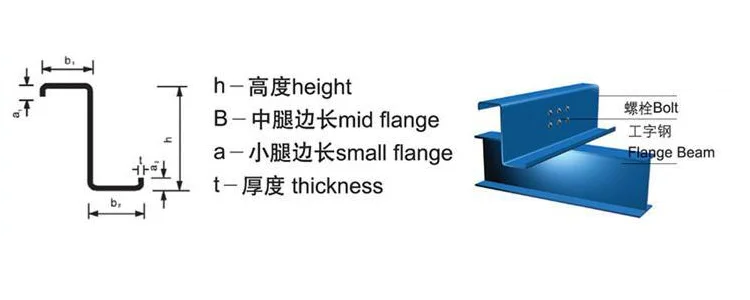

1.Profile drawing for reference:

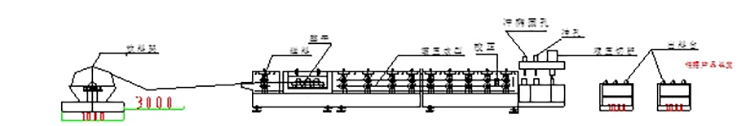

2. Working flow of Z purlin roll forming machine:

Passive Uncoiler—Feeding—Leveling– roll forming –hydraulic cut to length—output table

3. Technical parameters

- Formed Material: PPGI,GI,AI

- Thickness: 0.3-0.8mm

- Roller station: 18 rows(As your requirement)

- Diameter of shaft: 80mm solid shaft

- Material of rollers: 45# steel, hard chrome plated on the surface

- Machine body frame: 350 H steel

- Drive: Chain transmission

- Cutter: cr12mov material, no scratches, no deformation

- Motor Power: 22.5KW

- Hydraulic system power: 5.5KW

- Voltage: 380V 50Hz 3Phase(As your requirement)

- Forming Speed: The speed is adjustable

Structure: welded by the steel plates and profiled bar.

The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by Z purlin roll forming machine

2.Main Roll forming machine

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission, roller surfaces polishing, hard plating , heat treatment and galvanizational treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Feature: Ensure stability , precision and lifetime.

1. Roller fixer: guide column

2. Frame: steel plate welded/ Memorial arch frame type

3. Frame thickness: 25mm

4. Drive mode: chain

5. Material of rollers: Cr12

6. Material of shafts: 45#

7. Diameter of shafts: φ40mm

8. Number of rollers: 12 rollers

9. Main power: 11kw

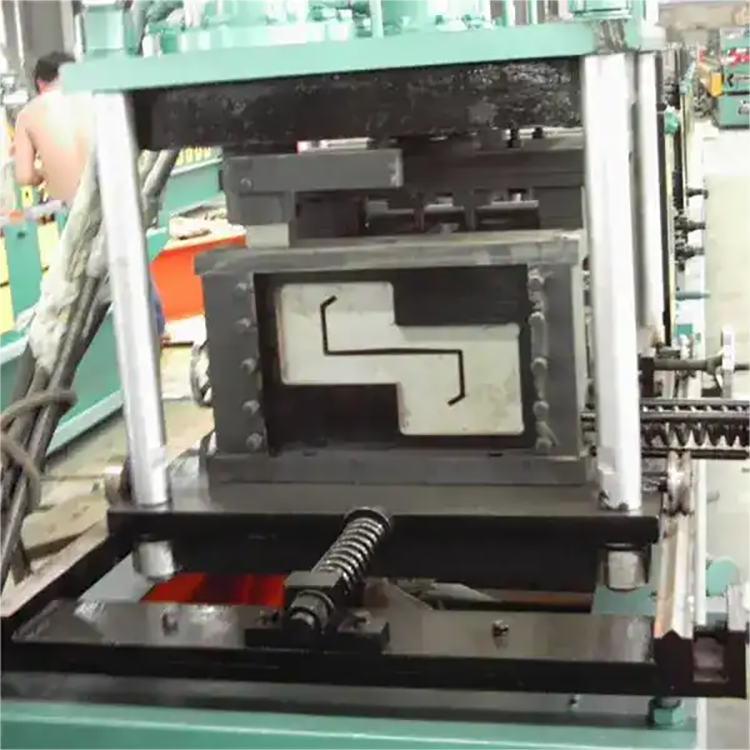

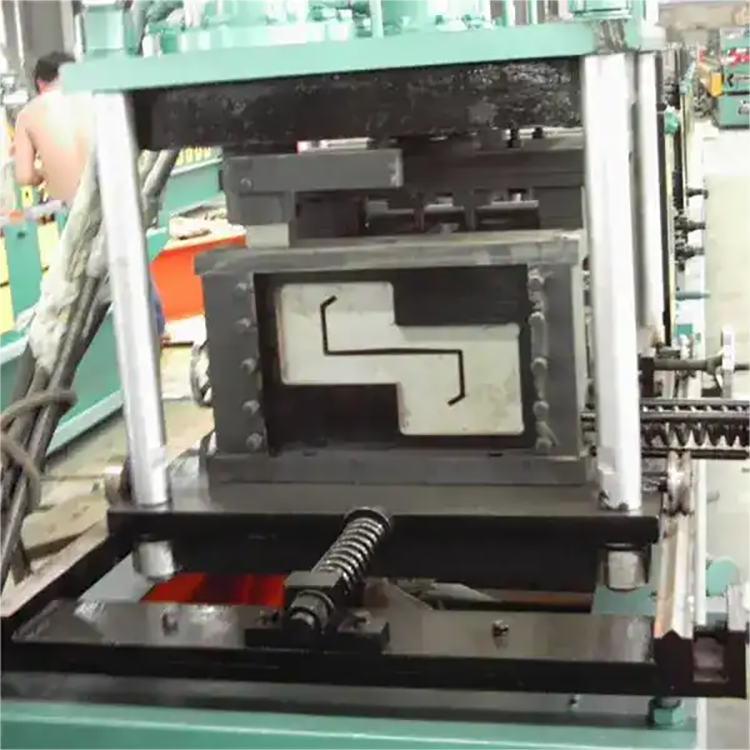

3.Punching Part

Punching is controlled by hydraulic pressure and mainly focuses on punching the middle hole of Z-shaped steel. It can be set according to your own needs, with or without punching. It is easy to operate, easy to use, and has good durability.

4.Automatic Cutting System

1. Feature: Ensure stability, precision and cutting speed

2. Function: Automatic cutting controlled by PLC

3. Material of blades: Cr12 quenched

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

5.Electric Control System:

1. Adopted PLC , transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2. Other electric element are Delta.

3. Equipped with movable switch , air break, radiator, transformer & electric leakage protector for operation convenience and safety.