C Z Purlin Roll Forming Machine

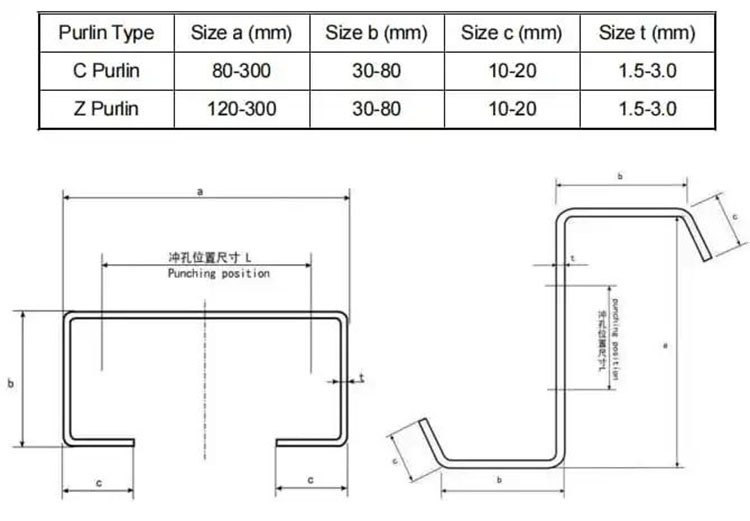

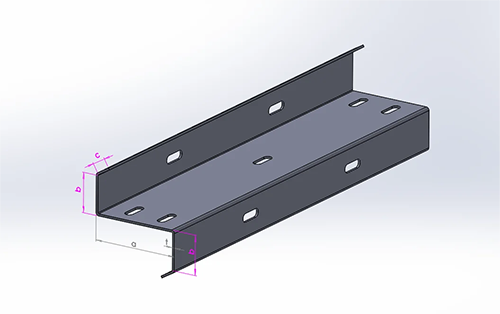

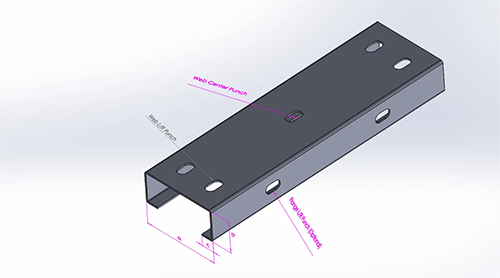

Profile drawing for reference:

Standard sepcification: Width from 80-300 mm(3-11 inch) , Thickness from 1-3mm( 15-9 gauge ) , other specail size we can also customized.

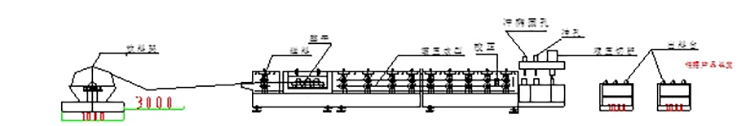

Processing Flow of CZ purlin making machine

Uncoiling—(Pre-cutting system)—Leveling & guiding—Main roll forming machine—Hydraulic punching—Hydraulic universal cutting—Runout table

Technical parameters

Raw Material:PPGI,PPGL

Material thickness: 1.5-3mm( 15-9 gauge )

Coil width: 150-500 mm adjusted

Machine Frame: Machine base frame is made of U beam weld steel. In the main roll forming machine, there are 2 buttons for urgency stop in case any malfunction happens.

Material Of Rollers:High grade 45# forged steel

Roller material: Cr12 CNC processing heat treatment to HRC: 58-60 ,finish turning

Forming Stations

Roller stations :20 rows

Diameter Of Shafts:Φ75mm solid

Material Of Shafts: 40 Cr CNC processing HRC28-32 ,finish turning and electroplate

Forming Speed: Max 30 m/min

Voltage: 380v/50hz/3p (As Requested)

Transmission Way: By 1.5 inch chain

Servo Power: 30KW

Cutting Blade Material: Gcr12 quenched treatment

Cutting Type: hydraulic post cutting

Control: Sizes adjust by PLC control and button C and Z section changing by PLC control

1. Max weight: 6T

2. Inner diameter: Φ380-580 mm

3. Max hydraulic pressure: 12MPA

4. Hydraulic station motor power: 5.5 KW

5. With or without coil loading car

Pre-cutting system

It’s used for cutting the coil strip before forming.

The pre cutter is individual controlled by buttons which is installed on cutting frame.

Leveling & guiding system

1. Leveling system: Top 3 and bottom 4 rollers, with extra 2 coulpe of pinch rollers.

2. Leveling roller diameter: Φ80/100 mm

3. Rollers are solid shaft with heating treatment, polishing and galvanizing.

4. Guiding system including guiding shaft and guiding rollers. Their width is adjustable in order to suit for verious steel strips.

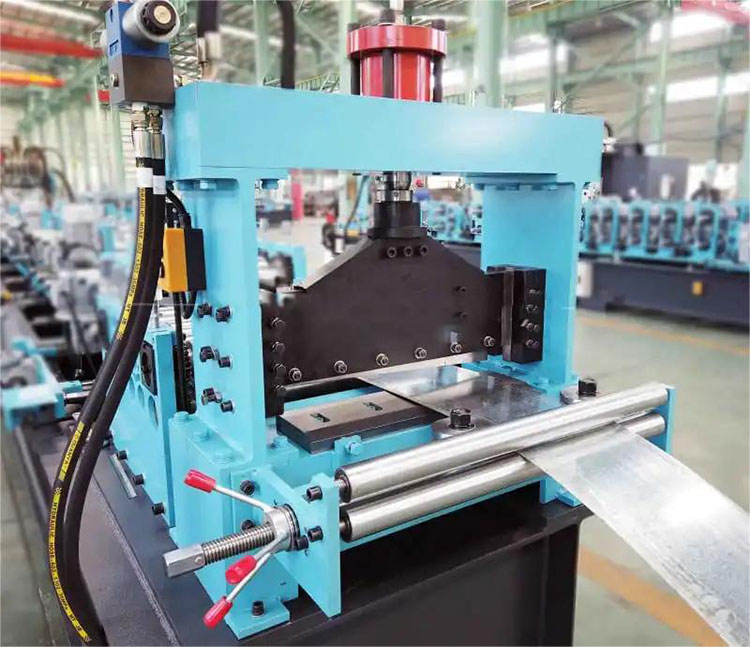

Main roll forming machine

1. Roller station: 18 roller stations, chains transmission.

2. Roller material: GCr 15 with heat treatment, polishing and galvanizing.

3. Main motor: hydraulic driving, power: 22 KW with air cooling system.

4. Machine frame: welded by iron plate, with flat planer finishing machining. The levelness is measured by electronic level meter.

Power supply and control system

Operation platform: HMI& buttons with English on it.

Control system: PLC(Ormon brand)

Key components adopts international famous brand

C Z Purlin Roll Forming Machine Advantage

1.Servo motor

Servo Motors are used throughout many industries and have the following advantages:

1. High efficiency

2. High output power relative to their size More constant torque at higher speed Closed-loop

3. control Quiet operation Highly reliable High ratio of toraue to inertia

4. High acceleration High-speed performance

5. Torque control

6. Smooth running

7. High accuracy

8. Well suited to varving load applications

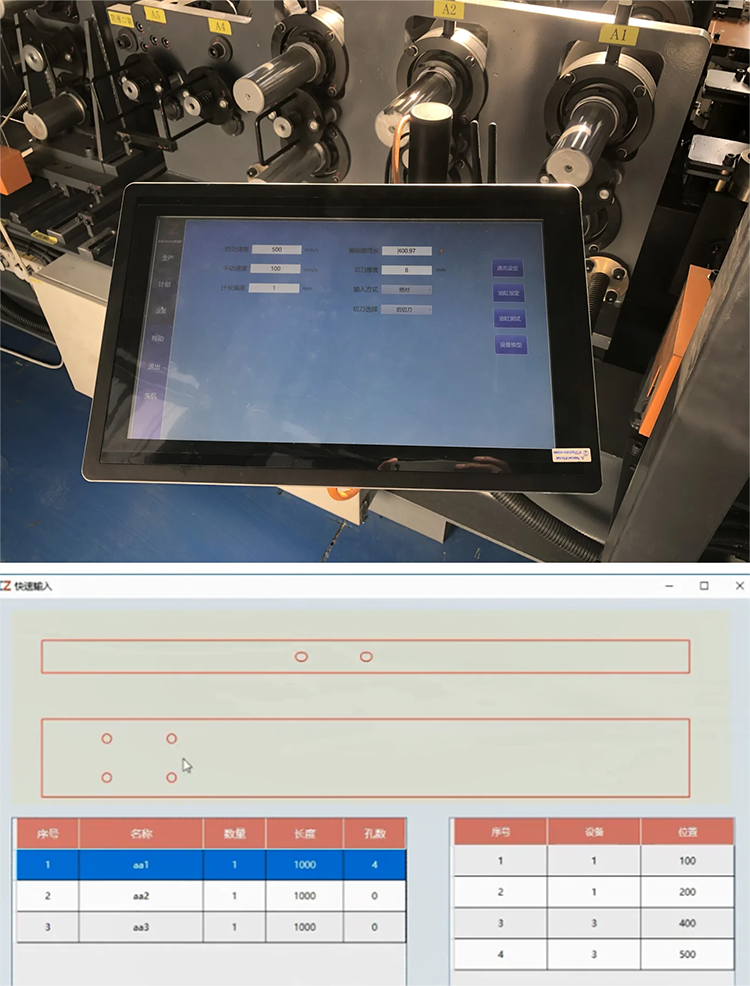

2.Laptop-type intelligent control system

1. Select domestic high-end leading servo motor brand series – quality, production efficiency, precision leap (production efficiency increased by more than 30%)

2. Upgrade the intelligent control system – more intelligent and superior

3. High-end portable laptop operation – high-end convenience, mobile office, production, more than one step ahead

4. The first self-developed intelligent fast input software in China – liberating tedious input, improving work efficiency, one step ahead, one step faster (saving about 1 hour of working time per day)

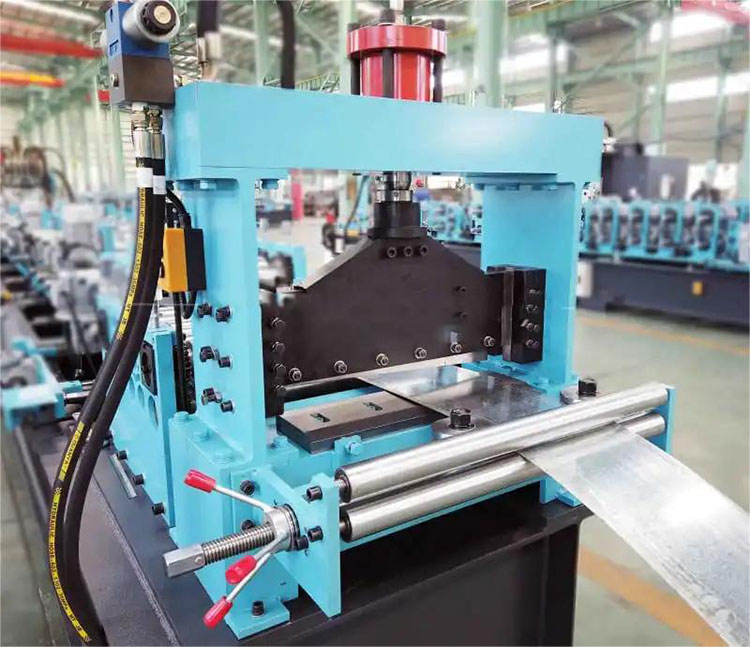

3.Puching Unit With Hydraulic System

Station 1: Pre-Hydraulic shearing

Station 2: Bottom center holes punching

Station 3: Bottom double side holes punching

Station 4: Each side flag holes punching