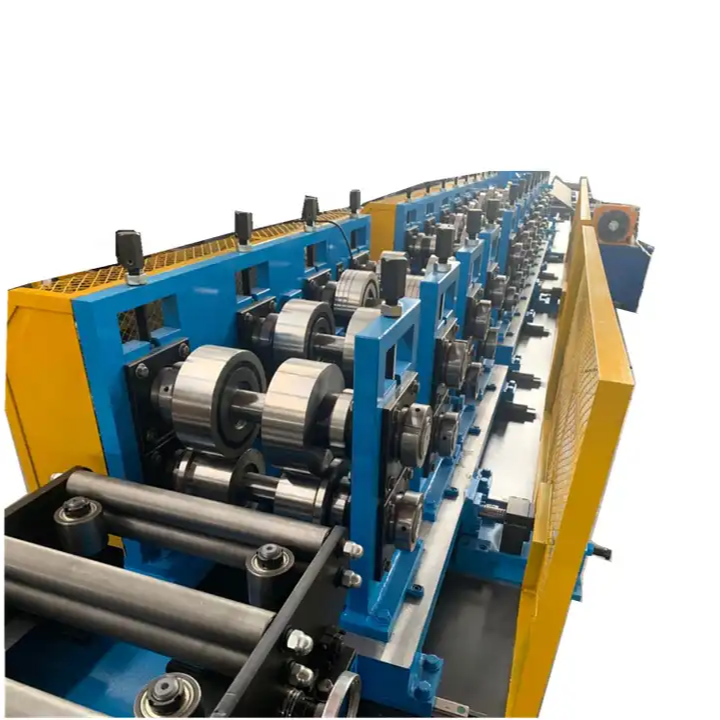

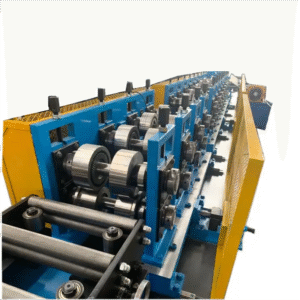

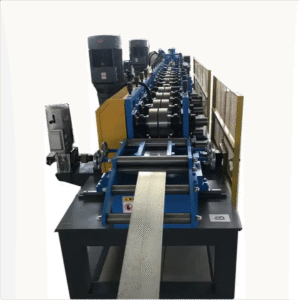

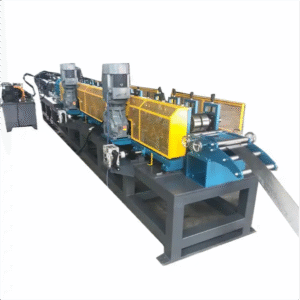

Stud and track roll forming machine

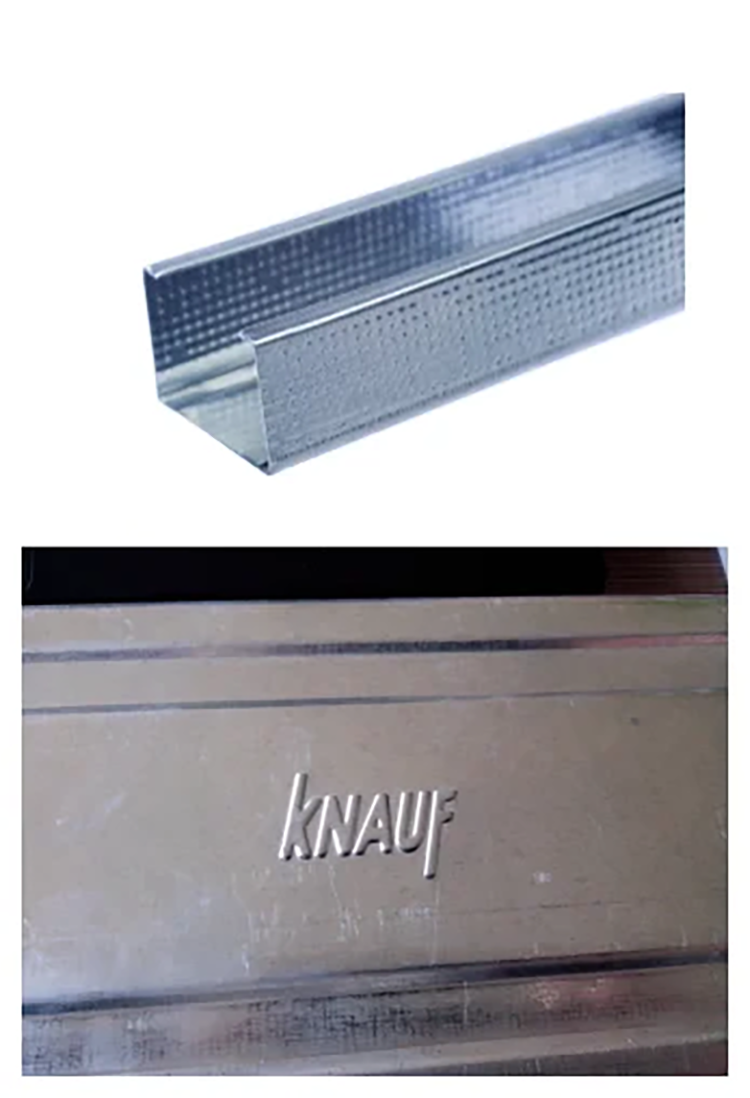

1.Can punching logos or ribs on channel if you need.

2.Support stud and track dimension customized, machine color and voltage customized as your request.

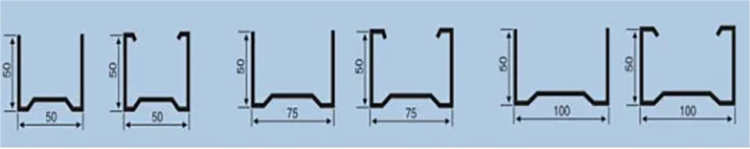

2.Profile drawing as below

Here is the C and U channel profile drawing and dimensions for your reference. In drywall system, stud will insert into track, so usually stud need punching holes. One machine can produce both C and U sizes by adjust the roller spacer manually or automatically. We have different machine speed for you choose, like 25 m/min, 45 m/min, 70 m/min with semi-automatic and full automatic type.

3.Product Parameter

Raw material:Galvanized steel

Material thickness:0.4-0.9 mm

Cutting length: Adjustable

1.Decoiler

Work type:Passive type

Loading capacity:3 Tons

Coil inner diameter:450-550 mm (adjustable)

Quantity:1 set

2.Roll Forming System

Feature;The one side machine frame can be move by PLC control to adjust the stud and truck dimension.

Rolling shaft:

Shaft material: 45# steel

Shaft diameter: 50 mm

Tempering treatment

Roller:

Roller material: Cr12

Quenched treatment

Rolling station number:14 stations

Work speed:0-40 m/min, if punching, 30m/min

Machine frame:Vertical iron arch casting frame structure

Bearing:Chinese famous brand Harbin

Work power:5.5+5.5 kw

Transmission:By chains

3.PLC Control System

Frequency brand: Delta (original)

PLC brand: Delta (original)

Screen type: Touch screen & buttons

Screen language:English/Chinese

Encoder: Omron

Low pressure electrical part brand: Schneider

Function: Cutting length and quantity control, speed adjustment control, dimension adjust.

4.Hydraulic System

Feature: The cutter have different holes according to the product dimension.

PLC brand: DELTA brand

Work type: Hydraulic track cutting with servo motor

Servo motor power: 2.3 kw

Hydraulic power: 3+5.5 kw

Driving method: By pillar type Cylinder

Cutter material: GB-Cr12

Cutting length tolerance:±1 mm/3 m

Cutting feature: Automatic cutting after forming, no distorting.