In modern infrastructure projects, highway safety guardrails are essential components designed to protect lives and property. To ensure the highest level of durability and consistency, manufacturers require advanced forming technology capable of producing high-strength guardrail profiles with efficiency and accuracy. Zhongtuo’s highway road guardrail rolling forming machine offers a complete solution tailored for producing a wide range of W beam guardrails and related safety barrier profiles.

This state-of-the-art roll forming equipment is engineered for producing standard W beam shapes widely used in road safety applications, including Single Side Single Barrier, Single Side Double Barrier, Double Side Single Barrier, and Double Side Double Barrier configurations. It is especially suitable for customers who focus on producing only two-beam guardrail systems, with precision shaping and automated processing built into every stage of the operation.

Advanced Roll Forming for Consistent W Beam Profiles

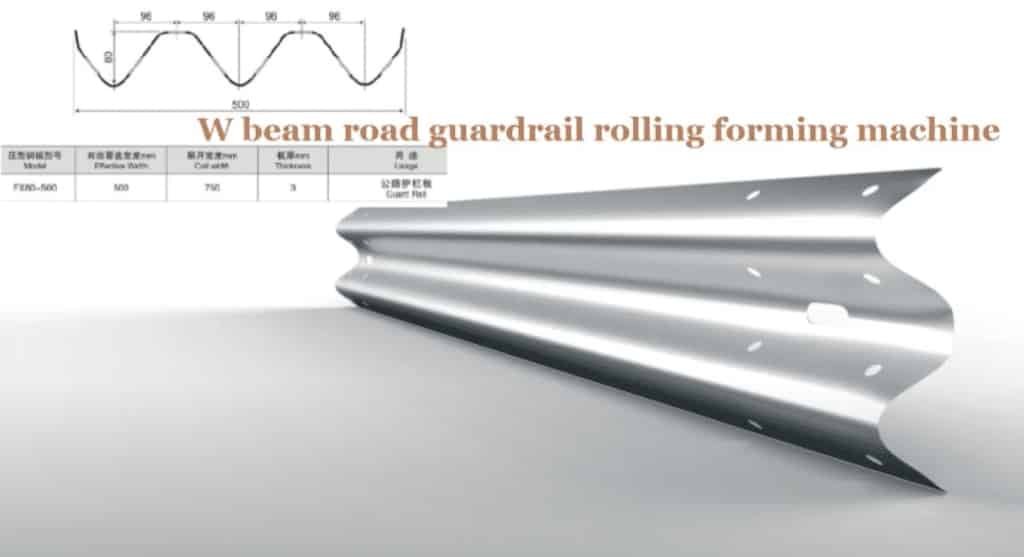

At the heart of the machine is a high-performance roll forming system that ensures the W beam profile is formed with smooth curves, accurate dimensions, and consistent wall thickness. The roll forming stations are built with hardened steel rollers mounted on solid shafts to maintain precise shaping throughout the production process. Each roller station is carefully aligned to prevent deviation, reducing scrap and material loss.

The guardrail rolling machine handles galvanized steel coils and other suitable metals with ease, supporting a variety of thicknesses depending on regional standards or project needs. The forming line’s robust design ensures the resulting beam profiles meet both national and international highway safety requirements.

Fully Automated Workflow: From Punching to Stacking

This highway guardrail forming machine integrates several automated systems into a seamless production line. One of the key features is the automatic punching unit, which precisely perforates mounting holes or slots into the guardrail beams as they move through the line. The punching unit is synchronized with the forming process, ensuring each hole is placed with millimeter accuracy.

After forming and punching, the guardrails are sheared to length and transferred to the automatic stacker. This unit carefully collects and arranges the finished beams for easy packaging or loading, reducing manual labor and minimizing handling damage. The end result is a neatly stacked, ready-to-ship product that maintains its form and quality.

Tailored Design for Two-Beam W Profiles

This particular roll forming machine model is specially designed for customers who produce only two-beam W-shaped guardrails. By narrowing the machine’s forming range, Zhongtuo enhances both the forming speed and the precision for the specified profiles. This focused design not only simplifies maintenance but also allows for quick material changeovers and tool adjustments when needed.

Whether you are manufacturing for government highway contracts, expressways, bridges, or municipal road projects, this machine enables you to produce industry-compliant guardrails with confidence and consistency.

Key Advantages for Manufacturers

Investing in Zhongtuo’s highway road guardrail rolling forming machine offers several clear benefits:

✅ High Production Efficiency

With automation across punching, shearing, and stacking, the machine operates with minimal labor input while maintaining fast output speeds.✅ Stable and Durable Performance

Designed for 24/7 operation, the machine features heavy-duty components built for long-term industrial use.✅ Accurate and Consistent Output

Servo-controlled positioning and advanced forming rollers ensure dimensionally accurate guardrails every time.✅ Reduced Labor Costs and Downtime

Automated systems eliminate the need for manual stacking and manual punching, improving workplace safety and lowering costs.✅ Custom Profile Support

While this unit is optimized for standard W-beam profiles, Zhongtuo can tailor the equipment to suit regional or specialized design requirements upon request.

Applications of the W Beam Guardrails

The guardrails produced by this machine are ideal for:

National and state highways

Urban roadways and bridges

Toll roads and express lanes

Construction sites and mining areas

Airport perimeters and rail tracks

Their function is not only to prevent vehicle crossover in accidents but also to visually define lanes and enhance overall road safety.