In today’s fast-paced warehouse and logistics industries, box beams are critical components in the construction of durable, high-load-capacity racking systems. As demand for flexible and strong shelving solutions increases, manufacturers need efficient and adaptable machinery to keep pace. That’s where the box beam machine comes into play—a specialized piece of equipment designed to produce roll-formed box beams with high precision, excellent strength, and customizable dimensions.

Material Compatibility and Thickness Range

The box beam forming machine is capable of processing various steel types within a thickness range of 1.0mm to 2.0mm. It supports a wide array of commonly used materials, including:

Pre-galvanized steel

Cold-rolled steel

Hot-rolled steel

This versatility allows the machine to accommodate different racking design requirements, whether for light-duty warehouse shelving or heavy-duty pallet storage systems. The forming process results in clean edges, uniform shapes, and excellent mechanical strength, making it suitable for both industrial-scale production and custom manufacturing applications.

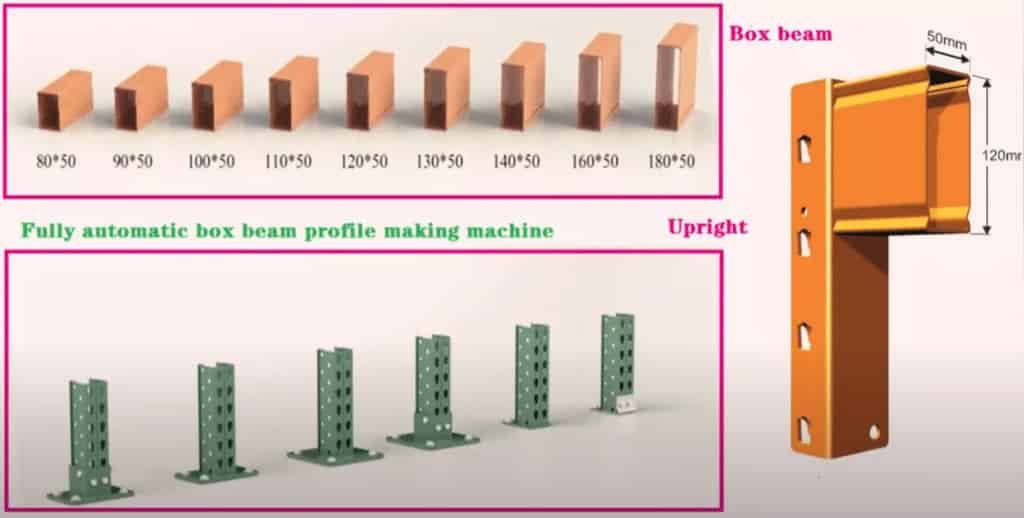

Standard Sizes and Customization Options

The machine is designed to produce a variety of standard box beam sizes, such as:

50mm

95mm

110mm

120mm

130mm

140mm

150mm

160mm

These dimensions are commonly used across global storage rack systems. For businesses with unique requirements, custom sizes are fully supported. Simply provide technical drawings or detailed specifications, and KINGREAL’s engineering team will design a tailored solution to match your production goals.

Structural Advantage: What Is a Box Beam?

A box beam is formed by mechanically combining two C-shaped steel profiles into a closed rectangular structure. This design significantly improves the beam’s load-bearing capacity, torsional resistance, and structural stability, making it a preferred choice in modern warehouse systems.

Unlike traditional open-section beams, box beams can handle dynamic and static loads more effectively and are less prone to bending or deformation under stress. They also offer improved safety performance, which is crucial in environments where reliability and long-term performance matter.

Easy Width Adjustment for Flexible Production

One of the most notable features of the box beam machine is its ability to quickly switch between different beam widths. By replacing specific roller sets and gaskets, operators can modify the forming dimensions in a matter of minutes. This modular design approach reduces changeover time and minimizes production interruptions, allowing for greater operational efficiency.

This feature is particularly useful for manufacturers producing multiple beam sizes or catering to varying customer demands. Whether switching between standard and non-standard dimensions, the transition is fast, user-friendly, and cost-effective.

Optional Automatic Width Adjustment System

To meet growing market expectations for smart manufacturing, the box beam machine can be upgraded with an automatic width adjustment system. This intelligent control system recognizes the product specifications in real time and adjusts roller positions automatically to match the required beam size.

Benefits of the automatic width adjustment system include:

Reduced operator workload

Consistent production accuracy

Faster changeovers for small-batch runs

Enhanced compatibility with Industry 4.0 smart factory systems

This functionality enables both mass production and small-scale custom orders to be completed with ease, making your production line more responsive to changing market trends and order sizes.

Enhanced Efficiency, Reduced Downtime

By combining a robust mechanical design with user-oriented features, the box beam machine ensures continuous, stable, and efficient operation. From coil feeding to final forming and cutting, each step is engineered for precision and repeatability. The reduced downtime between profile changes also improves overall plant productivity and reduces energy consumption.

In addition, KINGREAL offers optional automation components such as:

Servo-driven feeder systems

Hydraulic punching stations

Automatic stackers

PLC-based touch screen control panels

These additions further streamline your workflow and reduce the need for manual intervention, ensuring cost-effective production while maintaining premium product quality.

Ideal for Racking System Manufacturers

The box beam machine is a valuable asset for:

Pallet racking manufacturers

Warehouse shelving system suppliers

Cold storage rack producers

Logistics equipment manufacturers

With increasing demand for efficient space utilization and high-density storage, investing in advanced box beam forming technology is a strategic move that ensures long-term returns and customer satisfaction.