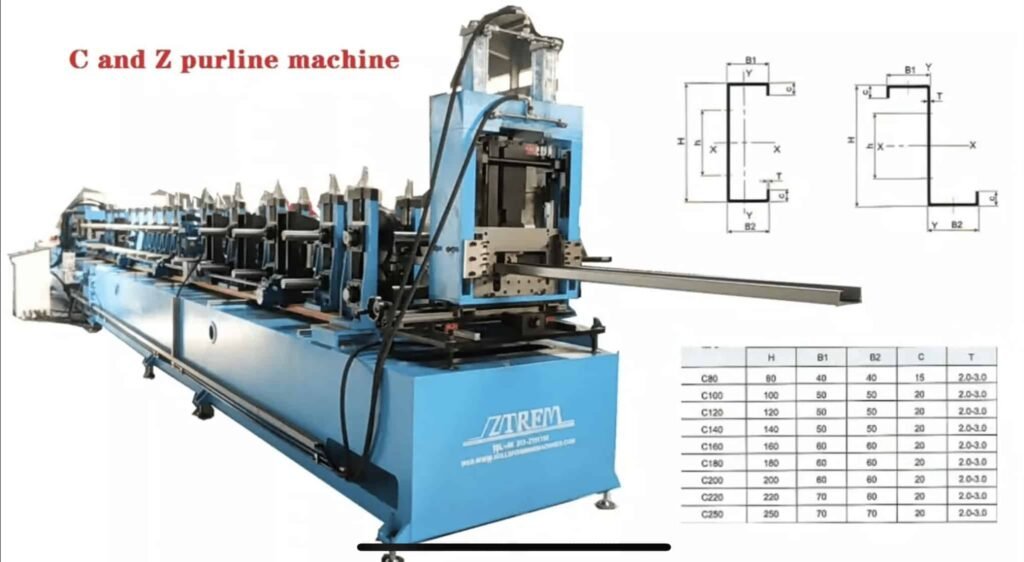

Take your metal framing production to the next level with our high-performance purlin roll forming machine, designed for maximum speed, precision, and versatility. This advanced equipment supports seamless manufacturing of both C and Z purlin profiles, ideal for structural steel applications in industrial, commercial, and warehouse construction. With intelligent CNC control, quick-change tooling, and minimal operator involvement, you can streamline your operations while reducing costs and improving output quality.

I. Engineered for Automated Precision

Our fully automatic purlin roll forming machine is developed for manufacturers who demand reliability and productivity. From raw coil loading to punching and cutting, the entire process is fully automated, eliminating manual handling and ensuring consistent results.

✅ Complete Automation Workflow

The system includes a decoiler, servo feeder, roll forming mill, punching unit, and hydraulic cutter, all controlled via an integrated CNC touch screen interface. Operators can set parameters, select profile types, and monitor production in real-time — with minimal training required.

✅ Dual Profile Functionality (C & Z Switching)

No need to stop the machine or manually adjust tooling. Our intelligent system supports automatic profile changeover between C and Z sections within seconds. This is particularly useful for manufacturers offering custom framing solutions across multiple projects.

II. High-Speed, High-Accuracy Performance

Speed and precision are the foundation of this purlin roll forming machine. Designed with servo motors and high-strength forming stations, it can achieve rapid production without compromising dimensional accuracy or product quality.

Forming speed: Up to 25 meters per minute

Material thickness: Handles steel between 1.5mm and 4.0mm

Profile width range: Adjustable from 100mm to 350mm

Thanks to its servo-controlled punching and hydraulic cutting, every finished profile maintains millimeter-level consistency — essential for structural reliability.

III. Intelligent Material Optimization

Our advanced nesting algorithm minimizes material waste during cutting and punching, allowing you to reduce scrap and save on raw material costs. Whether you’re working with galvanized steel, cold-rolled coil, or high-tensile materials, the machine automatically adjusts for optimal efficiency.

✔️ Smart Functions Include:

Material tracking sensors

Automated length calculation

Batch management by project

Defect detection and alarm system

With these features, production becomes both cost-effective and environmentally conscious.

IV. Key Benefits for Manufacturers

Reduce Labor Costs by Up to 70%

Because the entire process is automated, fewer technicians are needed on the shop floor. The system requires only one operator for setup and monitoring, freeing up labor for other tasks.

Quick-Change Tooling System

Switch between different profile dimensions quickly and without manual recalibration. Tooling modules are designed for speed and convenience, shortening downtime between production runs.

Cloud-Connected Monitoring

With IoT integration, you can receive real-time performance reports, maintenance alerts, and production logs via cloud services. This is especially useful for large-scale factories with 24/7 operations.

Durable and Energy Efficient

The machine uses high-efficiency hydraulic units and low-noise motors, designed for continuous operation with minimal maintenance. The robust frame construction ensures long service life, even in demanding environments.

V. Ideal Applications for This Purlin Roll Forming Machine

The versatility and efficiency of this system make it the perfect solution for a wide range of industries, including:

Roofing system manufacturers

Pre-engineered building (PEB) producers

Steel frame fabricators

Warehouse and industrial infrastructure companies

Construction material suppliers

Whether producing long-span steel components for commercial buildings or framing elements for temporary structures, the machine adapts to varying project requirements with ease.

VI. Optional Add-Ons and Customization

To enhance your production line, we offer a variety of optional components:

Hydraulic stacker for automated material collection

Auto punching die sets for custom hole patterns

Barcode printing modules for tracking and logistics

Remote diagnostics software for predictive maintenance

We also provide profile customization support for regional standards (e.g., ASTM, JIS, DIN) to ensure your products meet all structural compliance requirements.

VII. Why Our Machine Stands Out in the Market

When compared to conventional roll formers, our purlin roll forming machine delivers:

| Feature | Our Machine | Traditional Machine |

|---|---|---|

| Automation | Full CNC Control | Partial/Manual |

| Profile Change | Auto C-Z Switch | Manual Adjustment |

| Speed | 25m/min | 10–15m/min |

| Material Range | 1.5–4mm | 1.5–2.5mm |

| Tooling Time | <5 mins | >30 mins |

| Operation | 1 operator | 2–3 operators |

With this edge, you’ll gain the speed, flexibility, and product consistency needed to dominate your market.