In the evolving world of structural engineering, speed, precision, and flexibility have become the benchmarks for modern manufacturing equipment. Zhongtuo, a leader in the roll forming industry, has launched its upgraded purlin roll forming machine, tailored specifically for producing sigma purlins, along with other essential profiles such as C and U purlins.

This newly developed sigma purlin machine offers a robust and intelligent solution for fabricators and construction firms looking to streamline production and reduce operational costs without compromising on quality.

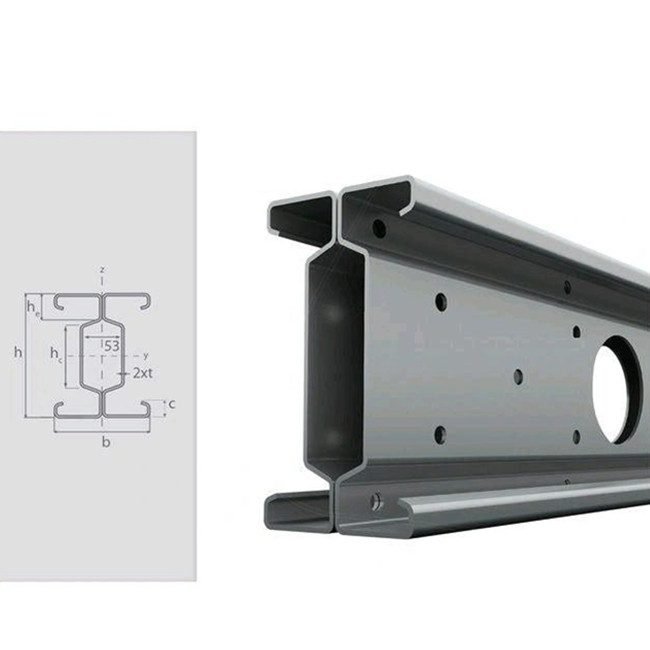

Why Sigma Purlins Are Special?

Sigma purlins are an efficient structural steel section, shaped similarly to the Greek letter Σ, and are widely used as secondary support structures in industrial and commercial buildings. These purlins are produced using high-strength pre-galvanized steel, typically grade S450, ensuring excellent durability and performance in various environments.

Their unique geometry provides greater load-bearing capacity and resistance to lateral torsional buckling, making them ideal for roofing and cladding systems in warehouses, factories, and prefabricated buildings.

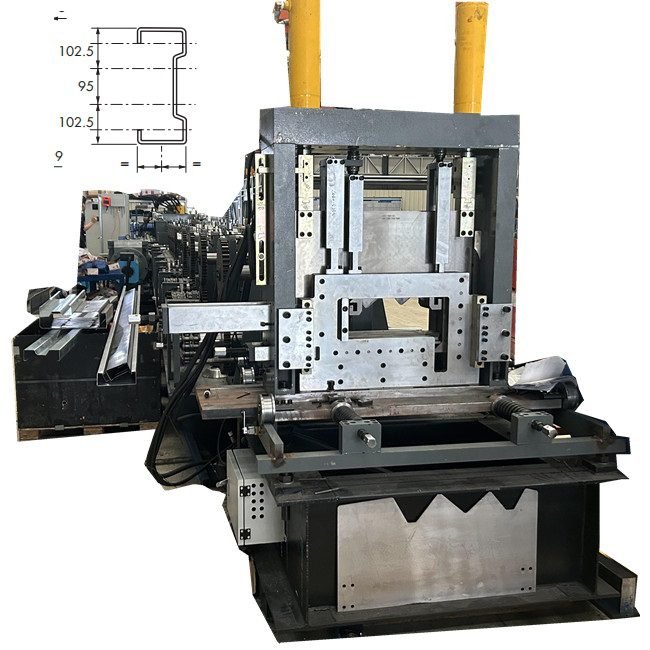

Introducing the NLT-400 Sigma Purlin Roll Forming Machine

The NLT-400 purlin roll forming machine has been engineered to deliver high-speed, fully automated production of sigma, C, and U purlins with remarkable accuracy. This machine represents the latest evolution in Zhongtuo’s cold roll forming technology and is designed to meet the needs of both small workshops and large-scale production lines.

Core Advantages:

Fully programmable size changes for width, height, and thickness

High-strength steel shaft and roller structure for long service life

Easy integration into existing production lines

Servo-driven motor with 68KW total power for stable, high-speed operation

Technical Specifications at a Glance

Supported Widths: 80mm to 350mm for C/Z/Sigma profiles

Waist Height: 30mm to 100mm

Material Thickness: 1.0mm to 3.5mm (ideal performance around 3.5mm)

Speed: Up to 15 meters/min (12–15m/min in practical use with punching)

Power Supply: 380V, 60Hz, 3 Phase (customizable)

Accuracy: ±1mm for length and hole positions

Control System: Computer input digital system with PLC and electric button transformation

Intelligent Design for Modern Manufacturing

At the heart of the NLT-400 system is its intelligent width-adjustment feature, which automates the configuration of the first 8 forming stations based on the desired profile size. The profile change process is simplified and requires minimal manual intervention, drastically improving overall productivity.

For applications requiring both C and Z purlins, the system supports manual switching, allowing operators to adjust tooling with precision and ease.

Advanced Material Handling and Processing

The NLT-400 follows a structured production flow that minimizes downtime and ensures a smooth operation:

Uncoiling

Material Feeding and Leveling

Punching and Pre-Cutting

Roll Forming with Sigma Rib Configuration

Receiving Table for Finished Purlins

This sequence allows for continuous high-speed production, supported by durable mechanical components made from Cr12 and 40Cr steel—both heat-treated and precision-machined for long-lasting performance.

Tailored for Real-World Applications

The sigma purlin machine is ideal for companies engaged in:

Steel frame construction

Warehouse and logistics infrastructure

Prefabricated and modular buildings

Renewable energy structures (solar mounting frames)

Agricultural steel structures

Whether the requirement is for heavy-duty industrial use or flexible job-site fabrication, this machine offers the customization and stability needed to meet a wide range of project demands.

Built for Performance and Reliability

Every aspect of the machine is engineered for long-term use:

Rollers are made from Cr12, heat-treated to HRC58–60 for surface hardness and resistance to wear.

Roller shafts are manufactured from 40Cr and CNC-processed to ensure tight tolerance and smooth rotation.

Double chain transmission system ensures synchronized performance even under heavy load.

Clear marking lines and scale guides simplify manual adjustments, while the servo-controlled drive maintains consistent speed and torque during all phases of production.