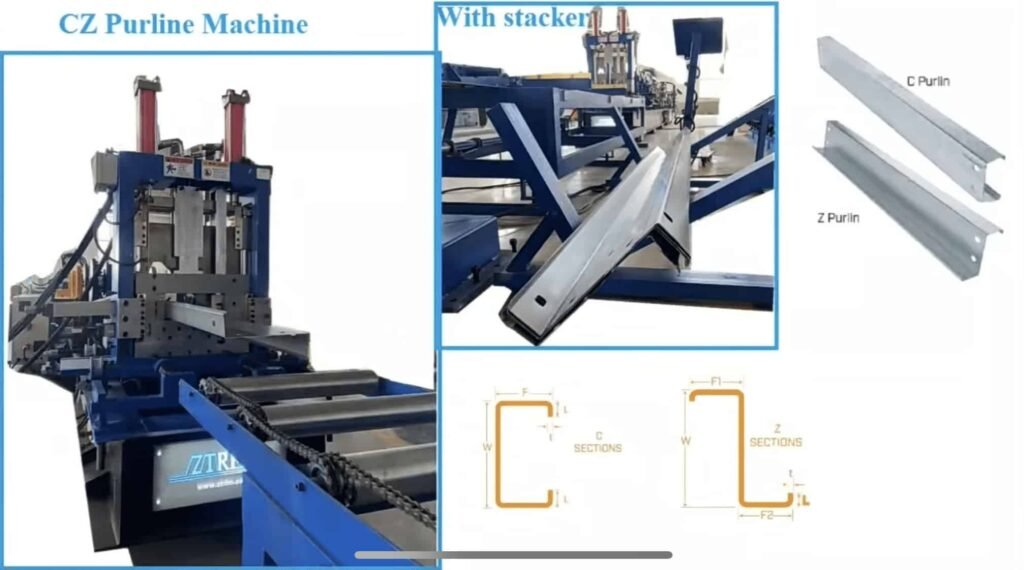

The CZ purlin roll forming machine represents the next evolution in metal profile fabrication. Engineered with intelligent post-shearing technology, adaptive controls, and seamless CAD integration, this advanced solution enables precision manufacturing of C and Z purlins for structural steel framing. Whether you’re producing components for industrial buildings, warehouses, or pre-engineered construction systems, this intelligent roll forming machine delivers accuracy, consistency, and efficiency at scale.

I. The Power of Post-Shearing Intelligence

Unlike traditional systems, this CZ purlin roll forming machine focuses heavily on precision after the shearing stage. This post-shearing intelligence ensures that each purlin is manufactured to exact specifications, reducing waste and enhancing structural integrity across your output.

✅ Precision Measurement After Shearing

With its intelligent measuring module, the machine continually monitors and corrects length deviations post-cutting. This helps:

Maintain consistent profile length

Prevent dimensional discrepancies in batches

Reduce material loss due to incorrect shearing

Such meticulous control is especially crucial when producing purlins for load-bearing structures, where even slight measurement errors can compromise performance.

✅ Enhanced Quality Assurance

By focusing on post-process accuracy, the machine achieves uniformity across large-scale production. This ensures:

All purlins meet industry tolerance standards

Improved product reliability in real-world applications

Stronger brand trust among contractors and developers

II. Intelligent Design Features for Smarter Production

What sets this CZ purlin roll forming machine apart is its integration of intelligent control software and automated design-to-production capabilities.

Automated CAD Drawing Interpretation

Forget manual parameter input — this system reads and interprets CAD designs directly through its built-in software. This feature streamlines operations by:

Minimizing operator error

Accelerating job setup for new designs

Allowing instant production of custom profiles from digital plans

This intelligent approach bridges the gap between design and manufacturing, making it ideal for companies managing diverse client requirements or frequent spec changes.

Adaptive Technology for Materials and Tasks

Material properties can vary based on supplier, coil type, or environmental conditions. The adaptive sensors and responsive logic in the machine automatically adjust to:

Thickness variations (e.g., 1.5mm to 3.5mm)

Coil strength and tension differences

Profile shape transitions between C and Z forms

This results in minimal downtime and consistent forming, regardless of batch differences.

Key Performance Highlights

| Feature | Description |

|---|---|

| Profile Types | C, Z (interchangeable via auto switch) |

| Material Thickness | 1.5mm – 3.5mm |

| Profile Width Range | 80mm – 300mm |

| Forming Speed | Up to 20–25m/min |

| Control System | PLC + HMI touchscreen with CAD compatibility |

| Punching | Hydraulic or servo-driven, programmable |

| Shearing | Intelligent servo shearing post-forming |

| Voltage Options | Customizable to local standards (380V/415V/220V) |